Wings: Electrical Decision Making

Of course the plan with my build is to leave the avionics decisions (and actual purchases) until as late as i can in the process - for the obvious reasons. However, as with the empennage, it is a lot easier to run wires for items before the area is closed up. In the case of the wings, this means drilling the 'systems holes' for the plastic grommets in each rib. I had initially thought i would just drill every hole to the maximum size (1/2") however since i had begun to draw up the electrical items for the empennage, i thought i would continue with the wire book and KiCAD drawings of the system and begin to populate the wings (virtually anyway).

In making up the wiring diagrams, i principally relied on the Garmin G3X install manual, while referencing both the

Van's master wiring diagrams and also the Dynon Skyview manual, just to make sure i was not boxing myself into a corner with my decision making. Each wire was drawn in KiCAD, then added to the wire book. The main reason for the wire book is so i can add the wire lengths gleaned from the Van's wiring diagrams, in order to order the required quantity of wire. These lengths will be cross checked against the wool i will use below.

|

| Wire Book entries for the Left and Right wings |

Equipment Locations

Time for some rough decision making (cue the forums!) - In the RV-14 this was fairly simple as there were some locations which were not disputable - for instance:

- Roll Trim must go in the right wing (at the innermost inspection panel)

- Roll Servo (Autopilot) must go in the right wing at the aileron bellcrank

- There is a nice ADAHRS bracket in the left wing, so this is the obvious choice for the magnetometer.

- Landing Lights (in leading edge cutouts)

- Nav / Strobe Lights (in wingtips)

- Fuel Sender wires (both wings)

The other items to be considered were:

- Heated Pitot Tube

- Pitot and AoA air lines

- OAT (Temperature Probe)

- COAX for a Wingtip Nav antenna (in the left wing)

Pitot Tube

The first decision related to the Pitot Tube was Left wing or Right wing. The Van's stock location for the Pitot is in the LEFT wing, one bay inboard of the left aileron bellcrank. This is fine for the Van's aluminium tube pitot, however I will be going for a heated pitot tube (brand TBA). Given the magnetometer will be in the left wing, i decided to place the pitot in the right wing.

This left 2 possible locations - one would be in the stock location (one bay inboard of the aileron bellcrank, accessed with an inspection panel on each side of the pitot), and the other is one bay outboard of the aileron bellcrank (accessed through the bellcrank access panel only).

Each place has it's own issues, with people on the forums with mixed opinions on the best path. Primarily it is a choice between the inboard location, with the possibility of the pitot tubes interfering with the aileron pushrod, and the outboard location where a tiedown rope could potentially interfere with the pitot tube. Who knows which opinion is correct - so at this early stage i will keep my options open, and plan for the pitot to be in either of the 2 locations.

OAT Temp Probe

Since there is a lot of items in the right wing already, the easy location for this is in the left wing. I will not be installing the stall warning vane in my aircraft (since i will have an AoA), so the inspection panel on the left hand outboard leading edge will be a good location i think (and the wires will fit through the existing hole in the spar).

EDIT: After looking on a number of forums, especially this recent discussion I found out there is actually already a hole punched in the left hand wing for an OAT probe - designed around the Dynon AHRS system, the OAT probe is adjacent to the first under wing inspection panel, where the ADAHRS mount is located - so this is the obvious choice for the OAT probe location.

|

| This is the left wing looking at the bottom - you can see the referenced hole adjacent to the inspection panel (circled in red). |

In summary, items will be located (probably!) as follows:

Left Wing:

- Landing Lights

- Nav/Strobe Lights

- OAT probe

- Magnetometer

- Fuel Sender, &

- Wingtip Archer Nav Antenna

Right Wing:

- Landing Lights

- Nav/Strobe Lights

- Autopilot Roll Servo

- Aileron Trim Servo

- Heated Pitot Tube

- Pitot / AoA Air Lines

- Fuel Sender

Connector Planning

For planning of the connectors in the wing root, the design goals were that i wanted to keep the wires from one component on the same connector if possible, rather than splitting a bundle between 2 connectors and also needed to observe the current limitations on the pins for each style of connector. This basically ruled out DSub connectors and i've never really been a fan of the molex connectors (especially the miniature ones). Deutsch connectors were another good option, with the DTM series (size 20 contacts) being good for signal, and the DT series (size 16 contacts) good for power (up to 13 amps). However, these come in a maximum of 12 contacts per connector, so would necessitate 3 connectors were wing.

Having considered all the of the above, I really like the CPC style connectors for the wing roots - these can be setup as a flange mounted on the fuselage side (meaning female sockets on the 'live side') and a male pinned plug connector on the wing side (aka 'reverse sex' connectors). The CPC connectors come in 2 series:

- Series 1 uses molex style pins, and these are available in both small gauge (20-24AWG) and large gauge (14-18AWG), both up to 13 amps - meaning these will be perfect for higher power devices / large gauge wires. Series 1 connectors come in 4,9,16,24 & 37 contacts normal sex, and 4,14 & 37 reverse sex). A 14 contact Series 1 should be sufficient for the higher power devices.

- Series 2 uses standard DSub pins (which i have plenty of) and are therefore suitable for 20-24AWG wires and circa 5 amps. Series 2 come in 8,9,28 & 63 contacts normal sex, and 8, 28 & 57 reverse sex). A 28 contact Series 2 should be well sufficient for the lower power devices (i could potentially use a smaller connector in the left wing).

When deciding what wires should be bundled together, the basic decision making process was that:

- Higher Power items should be grouped together

- Data Wires should be kept away from higher power wires due to noise.

In keeping with this idea, the following wire groups seemed to make sense:

Right Wing

- Autopilot Roll Servo, Trim Motor and Fuel Sender wires

- Landing Lights, Nav/Strobe Lights & Pitot Heat Wires

- In addition, there will be Pitot and AoA 'air lines' needed to come back to the panel

Left Wing

- Magnetometer and Fuel Sender Wires

- Landing Lights, Nav/Strobe Lights & Temperature (OAT) probe.

- In addition, there will be a RG400 Coax for a wingtip Archer Nav Antenna to come back to the panel.

EDIT: A note on the OAT probe - it seems that this is designed to be run without breaking the cable - i.e. run the probe all the way to the panel with no connector. Since i will be likely to have all the avionics installed and wiring done at home before the wings are put on, i think i will not include any wiring for the OAT probe at this time - leaving it until later. I will however plan for the probe to go through a connector just in case. This way i can simply install the probe in the wing before the wings are attached, and at that time make a decision on whether i wanted to run the probe wire through the connector or not - there will be room in a connector if required.

Below are 2 screenshots showing the current configuration for with wing connectors - the upper is the Series 2 (DSub pin) 28 position connector, and the lower is the Series 1 (13 Amp pin) 14 Position connector, which carries all the larger current items.

Right Wing Connectors - from top to bottom groupings:

Series 2 Connector (top) - 13 free positions:

- Roll Servo Can-Bus Wiring (2 Core, 22 AWG Shielded)

- Roll Servo Power & Ground (both 20 AWG) and 'Control Wheel Steering' (22 AWG)

- Roll Servo RS232 Data wiring (2 core, 22 AWG shielded)

- Trim Motor Wires (5 Core, 24 Jacketed)

- Fuel Sender (22 AWG)

Series 1 Connector (bottom) - 5 free positions:

- Landing Light Power & Ground (14 AWG twisted)

- Wingtip Nav / Strobe Lights (3 core, 20 AWG Shielded)

- Pitot Power and Ground (14 AWG twisted)

- Pitot State wire (22 AWG)

|

| Right Wing connectors. |

Left Wing Connectors - from top to bottom groupings:

Series 2 Connector (top) - 21 free positions:

- Magnetometer Can-Bus Wiring (2 Core, 22 AWG Shielded)

- Magnetometer Primary, Secondary power & Ground (3 x 20 AWG)

- Fuel Sender (22 AWG)

Series 1 Connector (bottom) - 4 free positions:

- Landing Light Power & Ground (14 AWG twisted)

- Wingtip Nav / Strobe Lights (3 core, 20 AWG Shielded)

Temperature Probe (3 core 22 AWG Shielded) EDIT: Perhaps! See note above

|

| Left Wing Connectors |

Routing of Wire Groups

Having worked out the wiring bundles, the design goal for the routing of these bundles was:

- Keep them as straight as possible to help with maintenance later on.

- Keep 'noisy' wires away as far as possible from data wires.

- Don't fill up the grommets too much to allow for future expansion.

Once all this was decided, i took to the shed with a bunch of coloured wool (don't tell the minister for war and finance) and worked out the wire runs. While a little hard to describe online i will give it a go!

Basically, there are 3 choices for holes in each rib - of course i can drill holes wherever i want, but i wanted to keep as close to Van's 'approved' locations as possible.

Having looked at the physical wing, i think the following is a good plan for wire routing:

Right Wing

- Autopilot Roll Servo, Trim Motor and Fuel Sender wires - Lower Forward holes out as far as the bay prior to the aileron bell crank rib, then up through an additional hole in the top of rib #9, then over the top of the top aileron bellcrank bracket straight to the roll servo. The trim wires would branch off this route after rib #4 to the trim motor (and if going Garmin, then the trim motor to roll servo interconnect wires could go back along the same route as above to the roll servo).

- Landing Lights, Nav/Strobe Lights & Pitot Heat Wires - Lower Aft holes, all the way from the root to the tip. The landing lights branch off through the grommet in the spar web to the landing lights.

- Pitot and AoA 'air lines' - Since there are no Upper Aft systems holes drilled, this will allow for 2 small holes to be drilled to carry the pitot line and the AoA line separately.

|

| Right Wing Root - the orange wool is the Roll Servo / Trim wire in the lower forward holes. The blue wool is the Landing / Strobe lights, and the green wool is the Pitot heat wires. The wool the the upper forward holes (brown) represents the 2 Pitot and AoA 'Air lines'. |

|

Here the orange wool represents the Roll Servo and Trim wires, branching up through a hole in the #9 rib, over the top of the aileron bellcrank bracket to the roll servo.

Also here you can see the green wool representing the pitot wires - there are 2 options - the bay left of the bellcrank, where the green tape is (alleviating the interference issue with the tie down rope) - this is the stock location, or the bay on the right of the image where the green wool is (alleviating the issue with the pitot lines interfering with the aileron pushrod). The left most position would mean 2 access panels (one on each side) to gain access to the probe which in the end may override any issues with pitot tube interference with the aileron pushrod. I.e. a one time problem to route the pitot lines, versus harder maintenance in the future / tie down issues with the aeroplane. |

|

| The blue wool represents the landing / Nav / strobe wires. The Landing lights branch off after rib #13 through the spar to the landing lights. On the right of the image is the left spar, where the bundle runs in the Lower Forward holes, and one the left of the image is the right wing, where the bundle runs in the Lower Aft holes. |

- Magnetometer and Fuel Sender Wires - Lower Aft holes from the root until after rib #4 where the the Magnetometer will be located. This way they do not cross, nor go near the landing / Nav strobe wiring.

- Landing Lights, Nav/Strobe Lights & Temperature (OAT) probe - Lower Forward Systems Holes all the way from the root to the tip. The landing lights branch off through the grommet in the spar web to the landing lights.

EDIT: The OAT probe will now be located in the same bay as the magnetometer (between ribs #4 and #5). Therefore the best location for this wire will still be through the lower forward holes, however instead of branching off at the bay prior to the aileron bellcrank, this wire will branch off at the magnetometer bay. I should be able to use an ADEL clamp on one of the fuel tank Z attach bracket bolts to hold this wire when it branches off.

- RG400 Coax for a wingtip Archer Nav Antenna - There are no upper aft systems holes, so I can drill a 3/8" hole for a grommet to carry some RG400 coax all the way from the root to the tip - i will crimp a connector on this after the wire has been run to keep the holes as small as possible.

|

| The orange wool represents the magnetometer wiring running in the Lower Aft systems holes. This keeps it well away from the Landing / Nav / Strobe wiring. |

|

| The Landing / Nav / Strobe lights in the left wing run in the lower forward holes - meaning they run right past the aileron bellcrank. This is not possible in the right wing, as they would have interfered with the roll servo actuator arm. In the left wing this is not an issue. I will likely add an ADEL clamp on one of the bellcrank bolts to hold the wire bundle. |

|

Here the blue wool represents the Landing / Nav / Strobe wires and the green is the OAT probe wires - which branch out of the bundle through the hole meant for the Stall Warning Vane and into the leading edge. The inspection panel in that location seems like a good spot for the OAT probe. EDIT: The OAT probe will now branch off at the Magnetometer bay as described above. |

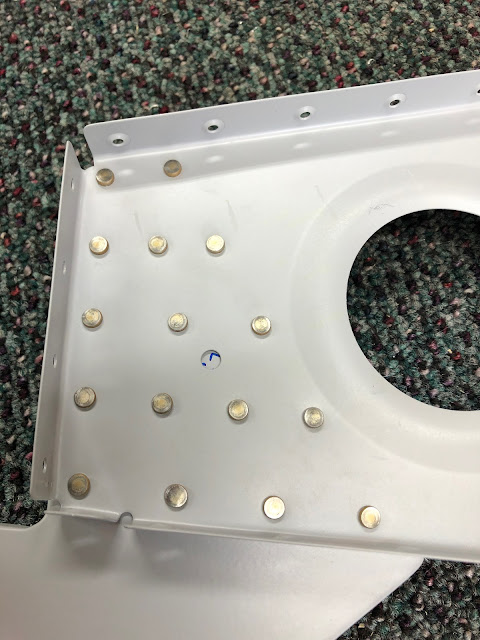

Grommet Sizing

The plans give callouts for the various grommet sizes but these largely don't make sense and are also designed for the Van's wire routing. Since i was doing something different, i needed to decide what size grommets i needed for each of the bundles above. I decided to measure each wire, then draw it in Word, placing the little circles inside a larger circle representing the grommet internal diameter. I then tested these using groups of wire off-cuts i had on hand to make sure they were right. You can see the grommets i have chosen in the images below, with a green square around them. In all other locations where I will not be running a wire at this point, i will drill to 3/8" for a SB-375-4 grommet. While this seems like the smallest grommet size, it in fact has almost the same ID as the SB-437-4 grommet, but has a smaller hole in the rib (so i think that is a good idea).

|

| In the above the trim wires run as a 5 core 24 AWG out to the trim motor, then 2 pairs of 22 AWG twisted wires run to the roll servo (this is the Garmin setup). If not using Garmin, then the trim wires would just terminate at the trim motor location (but at this stage, at least the grommets are big enough for both options). |

|

| While the SB500-6 grommet for ribs 1-10 (top green box above) seems a tight fit in the above image, on testing the 2 x twisted pairs of 14AWG wires (the brown circles) fit fine in the actual grommet with the other stated wires. |

Doing some actual work

Now that all this planning has been done, each hole has been marked up on the rib as per the above plan, then once the ribs are removed from the wing, i will up-drill all of the holes as per this plan!