Method to the Proseal Madness

The following was the procedure i have found to work the best when measuring and mixing proseal (although i bet it evolves throughout the build!).

I first set up all the equipment i think i will need which includes:

1. A piece of shop towel to protect the bench

2. 3 pairs of gloves (being worn!) - i only ever remove them down to the last pair and add more pairs over the last pair - saves the hassle of putting a glove on a sweaty hand.

3. A few bits of shop towel sitting next to the acetone (for cleaning as i go)

4. Scales

5. Mixing bowl that is tared for the weight of the mixing bowl, and also the mixing stick (i use tongue depressors from the craft shop to dig out the part A).

6. A small popsicle stick for taking out and adding the Part B

7. A large 60ml or larger syringe that has tape on the top to protect against the proseal when i fill it.

The process can be seen in the photos below:

|

| Ready for cleanup - you can clean your glove once or twice then it needs to be peeled off. |

|

| Setup (in this image i tried using a mixing cup, but the bowl works much better). |

|

| The bowl tared with the mixing stick - this was i can just pop the stick into the bowl to get the actual weight of the Part A on the stick - so you can avoid wasting this precious resource! |

|

| Part A added to the bowl - this is the real weight of the Part A. |

|

| 10% part B wiped onto the bowl edge with a small popsicle stick. |

|

| The tape helps keep the syringe clean |

|

| Loaded and ready to go |

|

| Works well! |

|

| Much less messy this way |

|

| Spread out with the tongue depressor |

|

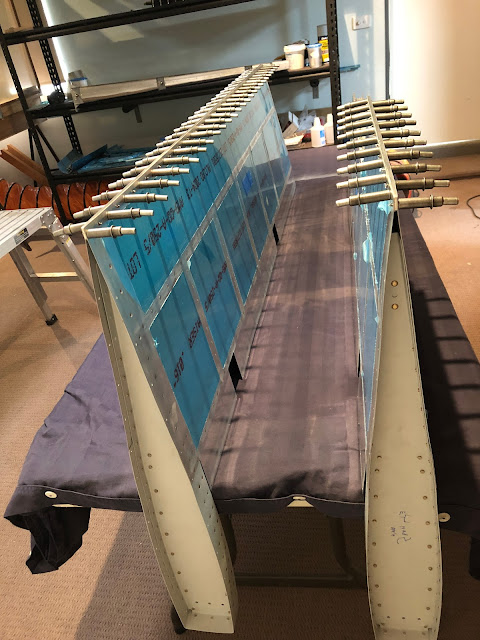

| Ribs installed - the cut off tongue depressors help keep the skin open. |

Once all the ribs were in place, i removed the sticks and gently lowered down the skin. I pulled the tape from the entire trailing edge piece before i lowered the skins. I then cleco'd from the centre outward.

|

| Good squeeze out on the rib edges. |

I also noticed that the trim tab had open ends between the closeout tabs and the trailing edge, so since i had some spare pro-seal, i filled these in as well. There is also a gap on the left elevator at the closeout tabs - so next time i have some proseal mixed up i will fill that too. (need to start a 'deferred jobs' list).

Trim Tab Hinge Pin

Since everything was curing, and i had a few spare shop hours, i cracked on - bent the hinge pin for the trim tab hinge. Drilled a 1/16" hole and I've ordered some 0.032 lockwire, and a set of reversible lockwire pliers which are both on their way.

Holy Molex

Had my first try and crimping micro-molex connectors which was pretty straight forward - my new wire stripper worked great. The only small issue was working out which way the pins went in to the connector, but got that figured out in the end. I riveted up the trim cover plate, and installed the servo. I then labelled and attached the wire extension, and added the silicone as per the instructions. I just used some Selley's clear Roof and Gutter silicone (i had in the cupboard) for this - it was only afterward i found a VAF thread talking about acid cure silicones and how they can corrode and ruin your electrics - doh! Luckily, the selley's website says it is a "Non corrosive neutral cure formula" - phew.

Counterweights

The final little task was to trim the counterweights. I tried using my bandsaw to make the cuts, but it just simply didn't work - the blade bogged down waaay too much for my liking. I tried a hacksaw, but the same was true. Finally i settled on a drop saw and this worked a treat, apart from the lead shavings everywhere. The backs of the internal counterweights were trimmed using a chisel and this worked perfectly. I tidied up the edges with the vixen file.

The last task was to install these weights as per the hardware shown in the plans - i measured the running torque on the MS21042-3 nuts at 9 in/lb, so the final torque value was 37 in/lbs, and i added some torque seal (and made sure it was not on the threads).

Riveting the Trailing Edges

Once a few days had passed and my coupon of proseal was cured, i cracked onto riveting the trailing edges. The first step was to close up the final rivets in the root and tip ribs. The plans have you use MK-319-BS pull rivets for the last 2 in the rib, but i only needed to do this for the very last one. I could fit my low profile squeezer in there - a must have tool i reckon.

The began by marking up the first round of riveting with a "1" - this was in the centre, at the ends and in the middle of those two. Then "2"'s were in the middle of the 1's, etc etc until i had 5 rounds of riveting to do. I marked these with a piece of tape so i would not get confused.

I then sat the elevator on the edge of the bench, and partially set each rivet with the hand squeezer in the same manner as the trim tab:

|

| All rivets are partially set with the squeezer. |

Once all the rivets were partially set, i had to shim up my backrivet plate so that the bend in the trailing edge was parallel to the backrivet plate. The plans seem to indicate a little bit of ply would do the job, but i found that i had to hang the counterweight arm over the edge of the table, and weight the forward spar, and i needed to raise the plate almost 2" up off the workbench.

|

| The plate had to be raised much more than indicated in the plans? |

Finally, i went along my #1s's through to the #5's and completed the riveting of the trailing edge. Initially the gun is kept parallel to the backrivet plate (and the current plane of the rivet), then is tilted as the setting of the rivet continues. I found it easier to do 3 separate bursts and move the gun angle between them, than one long burst. I ended up with only 1 smiley on the whole set of rivets (and it's on the underside so no big deal).

For the riveting on this section, the mushroom set us much too big, so i removed the spring and collar from the end of one of my back rivet sets - i reckon if i had done it this way on the rudder i would have ended up with a lot less smilies there too. It's a bit of suicide riveting but it seems to work.

Here's a sped up version showing the riveting of all the #4's:

Next up is the rolling of the leading edges, and the trial fit of the elevators on the HS.