The show must go on!

I learned early on in this build, where i encounter a stuff-up, it's best to go away, do some research and think about what the fix should be. From reading on the forums, a product called Weld-On 3 is commonly used to glue canopy cracks back together, so i ordered some of this. It is new year's eve, so I probably can't get my hands on it for a week or so anyway.

So - time to crack on!

Since all the tape had been removed from the fairing, and the fairing needed at least one more coat of paint, i applied some 3M fine line tape along the fairing edge, with some electrical tape on top. THis should give a very crisp edge. Another coat of paint was sprayed on (this was the 5th coat) - i am really getting good as masking these days.

|

| Fine line tape added along the faiting edge. |

|

| Electical tape added over the top, and a 5th coat of paint sprayed on. |

|

| Not many pin holes left - it's looking pretty good. |

Spray Paint On / Sand it off

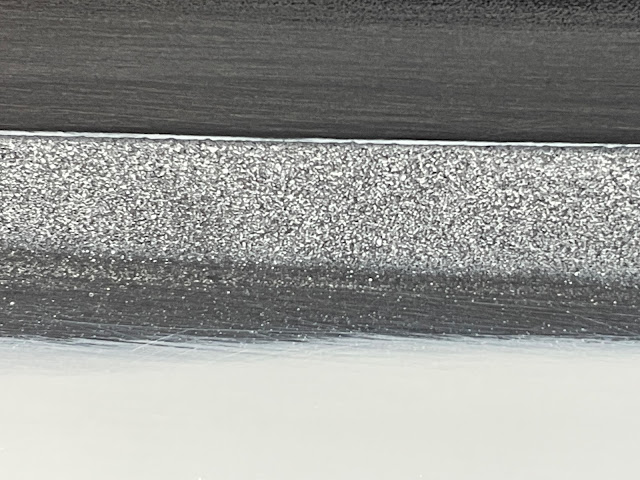

The 5th coat of primer was wet sanded using 400 grit. There seem to be a few pin holes still left, but there is no way i am hitting them with blade putty now! So a 6th coat of primer was sprayed on thickly. This was then wet sanded using 600 and 800 grit soft sanding sponges. All the pin holes are now gone, and the finish looks awesome. There are a few scratches where something got under the sponge, as well as a couple of areas where i've sanded some paint off ot the underlying surface. However, you have to make a decision at some point that you are finished - fibregalss work will go on forever otherwise. Plus, there couldn't be a 7th coat of primer without waiting a few weeks to get some more EkoPoxy from Stewart Systems in the states!

|

| 5th coat of primer sanded back wet using 400 grit. |

|

| She's got curves in all the right places. |

|

| There can't be a 7th coat of primer - because i ran out! |

|

| 6th and Last coat of primer applied |

|

| The orange peel is because i really put it on thick. |

Oh the glory it feels good to be done

Here are some glrory shots!

Here are some shots of what the fairing looks like from the inside - note that the canopy clips can be seen - thankfully these will be hidden by my glareshield cover, but for anyone following, consider painting these black (along with the canopy glass under them), before installation.

|

| I am very happy with the definition of this line. |

|

| Here you can see the canopy clip showing - i would paint it black along with teh canopy glass underneath next time. |

|

| Gotta have helpers! |

The canopy was covered over using GladWrap held on with tape - the tape applied to the painted surfaces, not the canopy glass, as it may end up being on there a while.

Moving on!

.PNG)

2.PNG)