For my firewall forward wiring planning, i have a couple of options for protecting the large 'bus feed' wires. If they are really big (greater than 6awg), there is a school of thought that you can leave them unprotected - if they short, it is likely to be of a short duration and with so much power that it just burns away the structure where the short occured. I think i want to protect the wires anyway!

The next option is using a large current limiter (ANL) or a large fuse (MIDI), mounted on the firewall in a fuse holder. This has a couple of disadvantages - namely that it takes up space on the firewall, and it required holes be drilled in the firewall for mounting.

The other option is a 'fusible link'. This is a short bit of wire, 4 sizes smaller than the wire being protected. The idea being that if there was a short on the main feed wire, the thinner cross-section wire would act like a fuse.

This seemed the best option, so i thought i would do some testing.

The Test

The test rig was pretty simple - a long bit of representative feed wire (in this case i tested both 10awg and 18awg), a butt-splice, then a smaller bit of fusible link wire (14awg and 22awg respectively) with a connector on the end (faston or ring). One end was connected to the positive clamp on my jumper leads on the car battery, and the other was connected to the negative side, thus creating a short.

For the fusible link wire i purchased some 14awg and 22awg silicone wire from ebay!

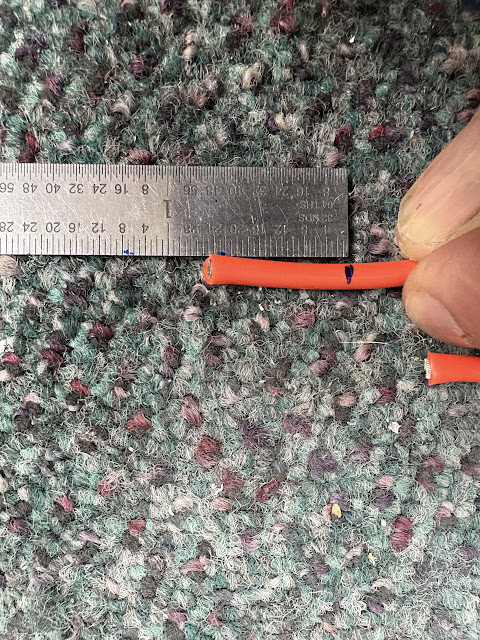

To make up the links, it was necessary to crimp two different sizes of wire into the one crimp. For the smaller gauges, the red crimp is sized for 18-22awg, so was able to crimp both sizes. The yellow crimp, however, is sized for 10-12awg. In order to fit the 14awg silicone fuse link into the crimp, i exposed a 3/4" length of insulation, splayed the wires out, then folded them back on themselves. Twisted together they then had enough diameter to securely fit into the yellow butt-splice.

|

| 3/4" stripping allows the folding over of the wire to inscrease it's cross section. |

|

| The 10awg tefzel was trimmed to just the required length, and went straight into the butt-splice. |

|

| The completed fusible link. |

This was the silicone wire i purchased from ebay:

The results

First up was a test of the 14awg silicone wire:

The test showed that it takes about 6 seconds to open the circuit. There was a considerable amount of heat generated, so much so that it melted the insulation around the faston terminal. If this was a ring terminal attached to a relay with a plastic housing, i would have concerns that the relay would be damaged by the heat. This would possibly we ok with a 'can type' traditional contactor.

|

| This shows the extent of heat damage to the faston connector insulation where it was crimped to the 14awg silicone wire. |

|

| The silicone outer insulation remained intact and the wire opened inside the insulation. |

The next test was the same setup, using 14awg silicone wire, but with a fibreglass sleeve impregnated with silicone aorund it:

|

| I used a 50amp MIDI made by Littlefuse MID050-32V |

Edit: Some Further Testing

Conclusions

- The silicone wire is a great product for fusible links. The fire and smoke is contained within the insulation totally.

- On the larger gauges, it really does take a considerable amount of time, and generate a considerable amount of heat. So much so that it damages the insulation on the faston/ring terminals, and i question whether it would cause damage to a relay with a plastic body.

- While the fusible link opens the wire, continual shorting and arcing can continue while there is still power available.

- If using silicone wire, the fibreglass / silicone sleeve is not really needed - however, i think i would use it anyway and try and cover the faston/ring terminals at the end as much as i can.

- Tefzel wire is a very bad product for a fusible link - if this is going to be used, then a fibreglass / silicone sleeve is mandatory! It threw molten wire across the driveway in this test.

- A MIDI fuse is so much less energy, but does require holes drilled in the firewall, along with a bit more expense (albeit, but really too much cost involved).

- The length of the fusible link doesn't seem to increase the open time of the link - but it seems to increase the energy required.

No comments:

Post a Comment