Canopy Hard to Close

Once the seals were installed, i put the canopy onto the airframe and sat inside - (yes, aeroplane sounds were made). I noticed that the canopy pins were hard to engage - when watching the canopy frame, you can visibly see it pulling the canopy down when the pins get engaged. Similarly, the canopy 'pops' back up when the pins are released. There is something holding the canopy up, which was not happening before.

This shows how far out the canopy frame is from the roll bar - this is looking aft into the hole toward the end of the canopy pin

Here you can see what is happening.

The TLDR was that some other pilots reported thier canopies were similarly hard to close - some said it might be too much sealant on the forward edge (but mine is ok). Some said it might be the aft seal binding - this was removed and checked, but it did not change how hard the canopy was to close.

This left the canopy glass as the possible culprit - it could be hitting the roll bar, before the canopy frame is in alignment.

I had previously asked a question on the forums about the canopy frame being below the level of the roll bar, prior to drilling the canopy. Once the canopy was drilled, the aforementioned gap dissapeared as the cleco's were installed. So i assumed this was not really an issue.

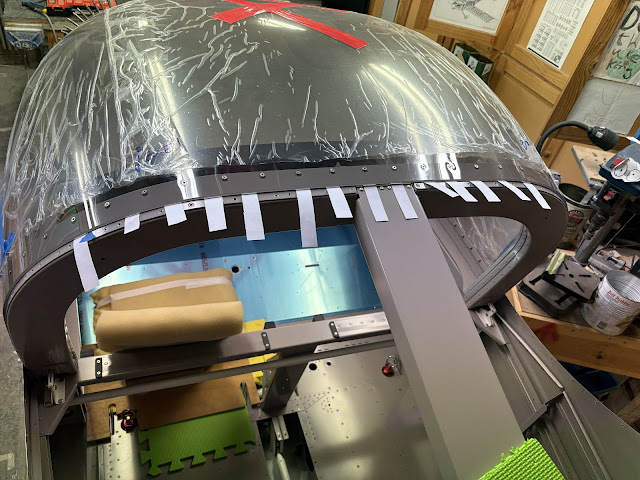

However, now the canopy is hard to close, it became the prime suspect. To test this theory, a number of paper strips were added along the canopy, between the canopy glass and the roll bar. The canopy was latched, then I tried to pull them all out - some places the paper could not be pulled out, and i marked these locations.

For the length of canopy along the marked areas, each screw was removed and a #8 (1/32" thick) nylon washer was slid into the gap between the canopy and the roll bar. I used #8, as it made for a larger bearing surface, as well as being easier to slide into position where the screw could be installed.

|

| Here you can see the nylon washers in position, before the rear seal was re-installed. |

The rear seal was then re-installed, and the canopy was test closed again. It was much easier to close - so i think this has solved the issue. I added the paper back into the canopy, and all the papers bar 2 at the very top could be removed. I left this as it was.

Canopy Side Pins

I elected to polish the side pins along with their matching plates, and the side pins were riveted on.

|

| The centre punch was drilled to 1/16" |

|

| These were a real pain in the ass to countersink! |

No comments:

Post a Comment