Now the canopy glass was done, i installed the glareshield cover. It actually fit very well first try - with only one small area on the right hand side which might need some fettling later on.

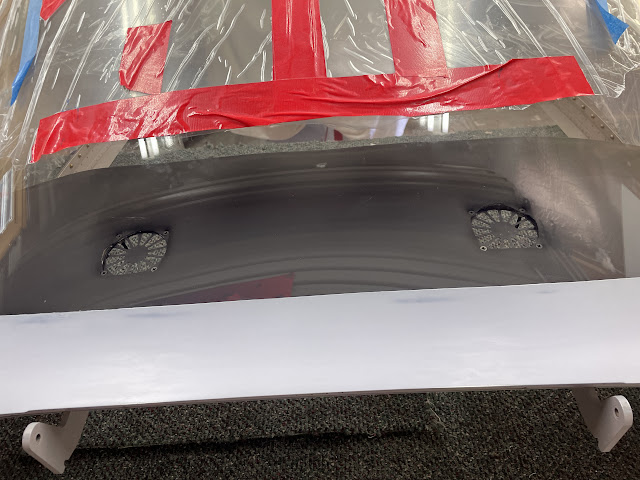

The cover was basically slipped into position, sliding the rubber tube over the canopy skin. The fan bezels were installed from above, with the screws poking through, and the fans and hardware installed on the underside of the canopy.

Finally, the leather was pulled under and velcro'd into position. I am very happy with how this turned out. It is very secure being held by the fan bezel screws, and the rubber tube along the aft edge. The foam gives it a very nice feel, and also makes the fan bezels very flush. The LED strip pocket worked well (i think anyway). We will see once i get the strip eventually installed.

|

| More helpers. |

|

| The underside worked out well and seems secure onto the velcro. |

|

| I'm glad we designed these - they worked well, and look good in my opinion. |

The fan bezels were printed using ANYCUBIC Rigid 100 Resin - this is apparently "

High-temperature resistant resin prints strong models, up to 100°C. Resistant to deformation in 60-100°C environments. Ideal for outdoor gear, electronics, and high-strength tools.It is currently the strongest resin offered by Anycubic."

No comments:

Post a Comment