Well, this was a bit of a journey, but i will try and logically lay out the steps i took to repair the leak in the right tank.

Cause

The first comment is what i believe to be the cause of my issues - when i was placing the baffle down, it was aligned such that the baffle was hanging over the root end of the rib (where the leak ended up) by perhaps a quarter of an inch. I did not do a good job aligning it with my fingers when i dropped it down into place. I did not think it was a good idea to lift if off again, as it had come into contact with all the carefully laid down sealant beads, so i just pushed it gently outboard to align all the holes.

This meant on the root end, i was pulling the bead at that end (which had stuck to the web of the rear baffle) away from the end rib flange. It is my belief that this is what caused my issues - so for anyone following, make sure you extend your fingers and align the baffle with each end when you drop it down.

1st Try

As mentioned in this post there was a small open section in the sealant which was in the same location as where the leak was, so i made an assumption that there was probably where the leak was stemming from.

|

| I believed this to be the offending location |

So i had to cover this area with sealant. Luckily, this was quite close to the location of the fuel sender hole - so i removed the sender screws and cut the sealant bead around the sender flange with an exacto knife. I then used a pallette knife to gently pry the sender out of it's bead of sealant.

Once it was off, the sender, the rib flange and all the screws and lockwashers were all cleaned of sealant using scrapers, a toothbrush and acetone.

In order to ensure that any additional sealant would stick, i used a rag soaked in acetone on my finger to get clean the existing sealant. I was able to reach this area with my finger.

|

| A piece of aircraft canopy made into a scraper |

|

| The sender after removal |

|

| The offending area after cleaning up with acetone. |

Once this was done, i applied as much sealant as i could to this area. I found the easiest way was to just put a blob on my finger and squeegee it into place.

Here you can see the location of the additional sealant and how it has definitely covered the offending location. It was spread along the flange as far as i could reach with my finger in each direction.

2nd Try

After 5 days to let the sealant cure, i set up the manometer again - and she STILL LEAKED in the same location as before. The manometer was showing a solid leak.

I was honestly surprised and confused at to how this was possible. I decided to get the borescope back into the tank to have another look. The only section which was still exposed from the original sealant application was in the corner, adjacent to the fuel drain location. I was unable to get sealant into this area the first time around because my finger didn't reach.

So i had to get creative - in order to clean this area before further sealant application i bent a plastic toothbrush handle using the heat gun, and was then able to get inside to clean this area. To actually apply the sealant, i was able to snap a tongue depressor in 2, and tape it to the end of my finger. This allowed me to get to the corner to smear sealant into that location.

|

| Using the bend toothbrush to get into the corner. |

The fuel sender was cleaned up again, sealant reapplied and the tank closed up. Fingers crossed once more.

3rd Try

After 6 more days to cure, i came back to the tank and was AGAIN distressed to see that the tank was not holding pressure. However, this time the leak was not in the same location along the rib flange - it was leaking out of the flange of the fuel sender!!!

I must not have sealed this correctly. So, time to remove it again!

It was resealed properly this time after a good cleanup of all the flanges and the screws.

|

| Sealant is applied to the rib flange |

|

| The screws are ready to go with Loctite 565 |

|

| I remade the sender ground wire as the locknuts had damaged the terminal after no many repeated installs. |

|

| The sender installed (hopefully for the last time). |

4th Try

Finally, after 4 more days to cure, i went back to the tank and set the test up. THE PRESSURE SEEMED TO BE HOLDING!

I left the tank for a while to make sure it was all ok, but the temperature in the shed was increasing that day and the manometer flowed over - in fact, it squirted blue liquid all over the walls and the storage shelf, staining my left wing top skins! (doh). Not to mention a big blue stain on the carpet. Oh well.

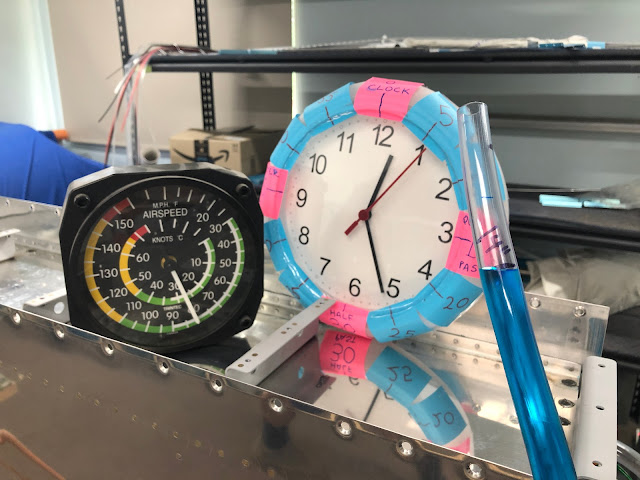

I waiting until around 8:45 PM and setup the manometer again.

|

| 8:45 PM - 30c and just above the line. |

Came back the next day:

|

| 7am the next day - 21C and the level has dropped a lot. |

|

| 9:30am - temp has risen to 23C and the level has risen |

|

| 10:30am - temp is now 25c and the level risen even more. |

|

| 11:30am - temp now 26C and the level still rising |

|

| 12:10pm - now 28C and not quite up to where it started |

|

| 12:30pm - 27C and up to the same level. |

It should be noted that the water level got back to the same level as where it started, but the temp was 3-4C lower than the starting temp. During this time there was about a 3HpA drop in atmospheric pressure, so i assume to accounted for the additional help to rise back up to the line with the lower temperature.

Having said all this, i am happy to confirm that FINALLY:

Postscript

Ever wonder what the 1psi does to the tank during testing? I was surprised how much flex the tank has. This was taken at the point in the video above right before, then after the manometer flowed over and released all the pressure:

Diesel tank leak fix Nova Scotia

ReplyDeleteAir dryer not building pressure repair Alberta